Training Courses

Courses

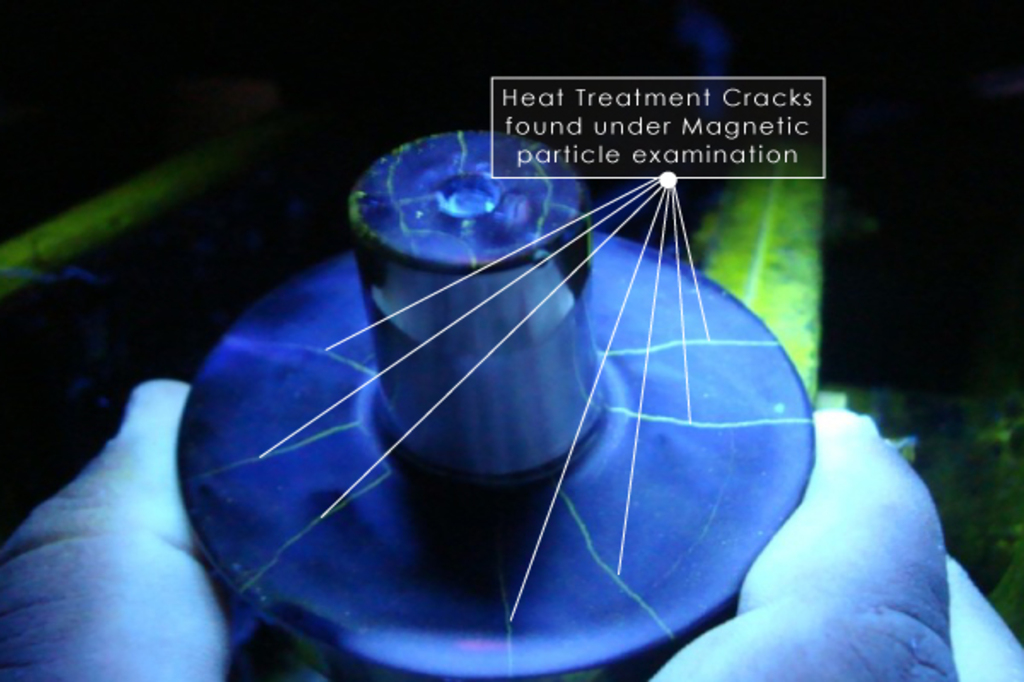

Magnetic Particle Inspection

Liquid Penetrant Inspection

Ultrasonic Testing

With this NDT testing service, one can use ultrasonic waveforms that pass through a material to detect flaws and provide a complete volumetric inspection. It is often performed on steel and other metals and alloys, and is used in many industries including steel and aluminium construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors.

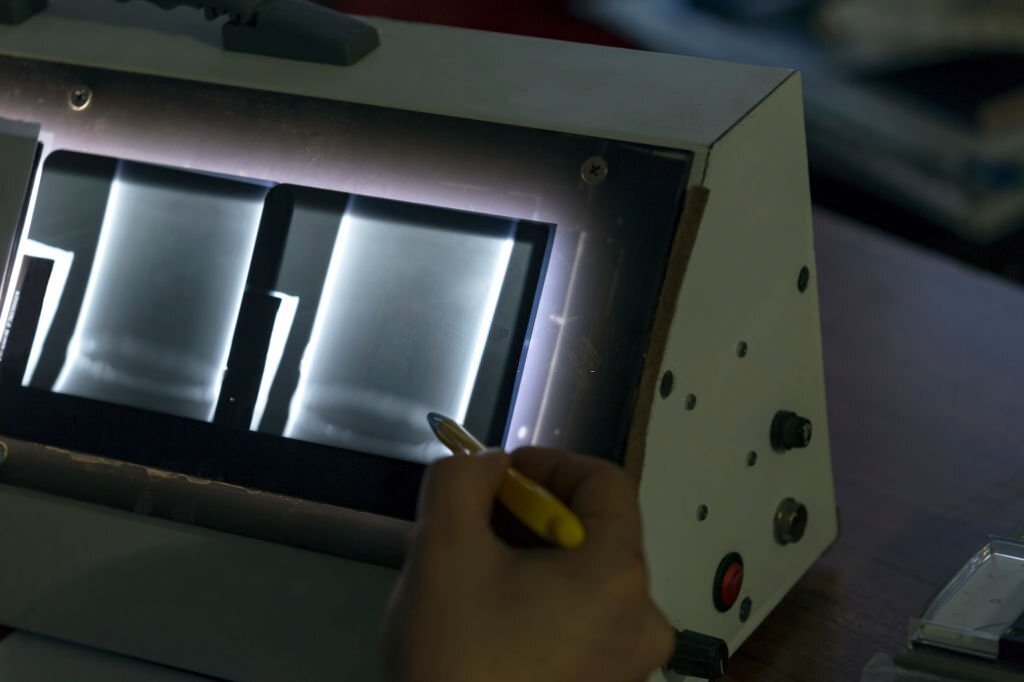

Radiographic Testing

Visual Testing (VT)

SITS provides a wide range of visual testing training services that in most cases can be the first method of inspection to detect any defects and observe problems in the earliest stages of fabrication. This most commonly used NDT method across all industries allows for a feasible and fast control of quality at every step of maintenance

RTFI

Radiographic films with natural and artificial discontinuities in welds are being provided for the practical. Understanding the basic principles of the radiographic inspection procedure, recognizing limitations in exposure quality and assessing radiographic quality, etc., are provided.