WHY CHOOSE US

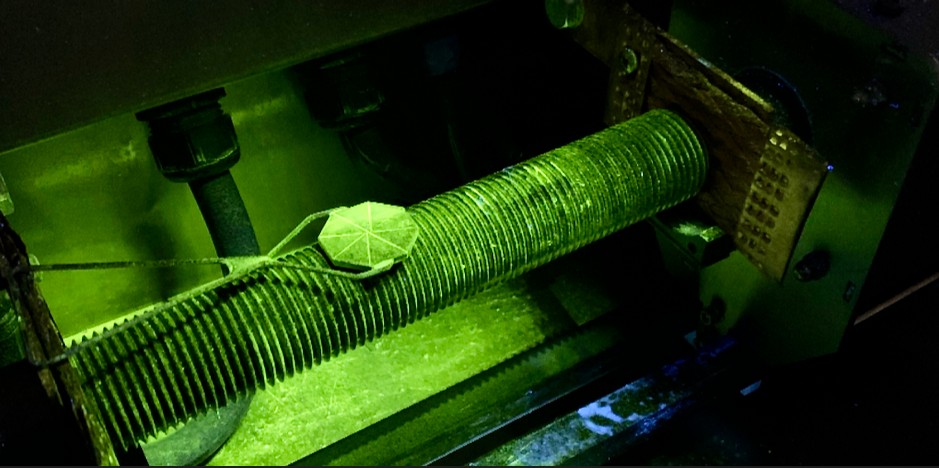

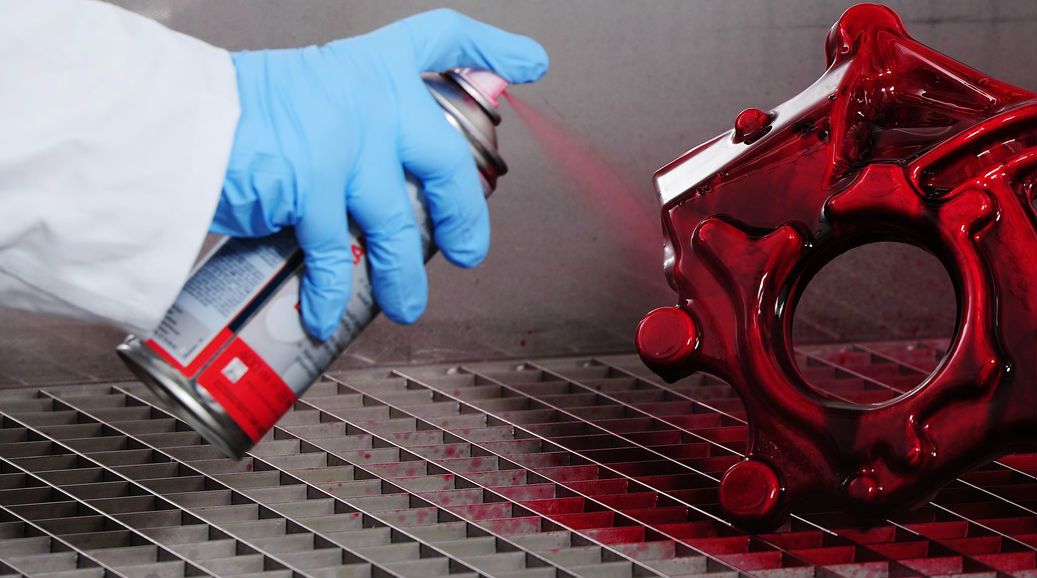

SITS provides you with a wealth of industry-focused technical education as well as live hands-on practical workshops. All of our courses and modules are designed to prepare participants to work by providing them with solid practical and theoretical knowledge

- Students can benefit from expert and experienced trainers who can help them learn more.

- Following an initial training consultation, customised training plans are created for each client.

- Our courses provide interactive learning opportunities.

- We are driven by a desire to see our clients succeed and advance in their professions.

- A wide section of courses are available

- We are constantly receptive to our clients' needs.

- Every effort is made to ensure a healthy and secure atmosphere